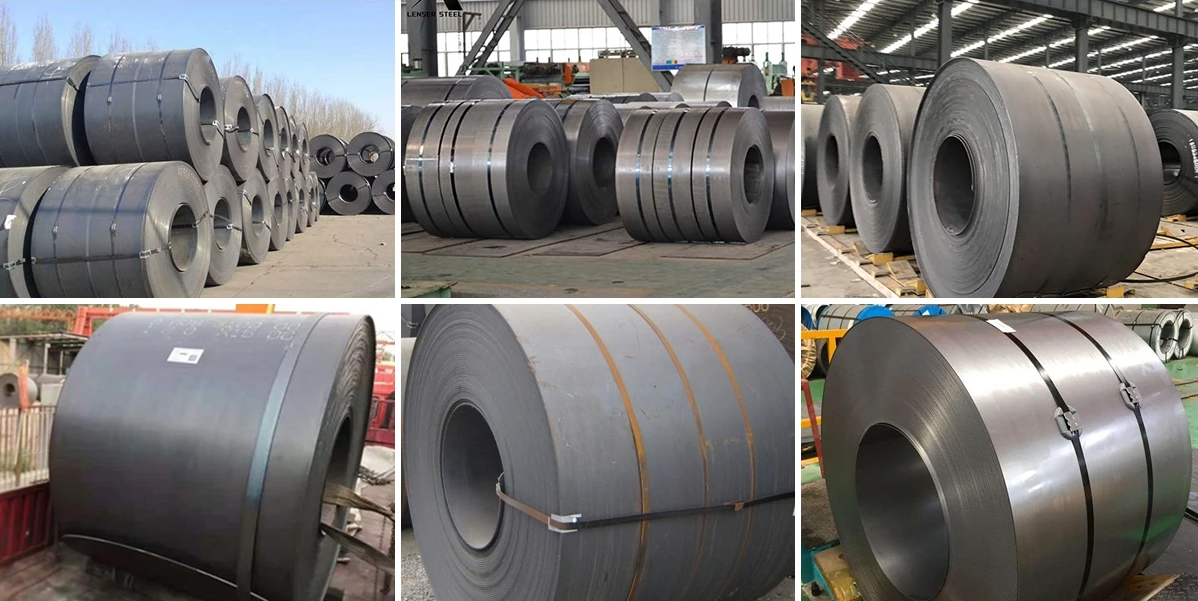

Ikhoyili yentsimbi eqengqelekayo ebandayo

Ingcaciso yeMveliso

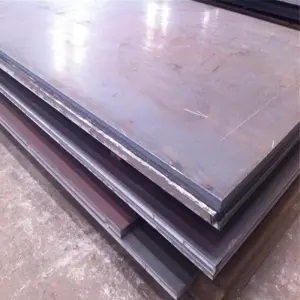

Ipleyiti yentsimbi yekhabhoni ye-Q235A/Q235B/Q235C/Q235D ine-plasticity elungileyo, iyakwazi ukudityaniswa, kwaye inamandla aphakathi, nto leyo eyenza ukuba isetyenziswe kakhulu ekwenzeni izakhiwo ezahlukeneyo kunye nezinto.

Iiparamitha zeMveliso

| Igama lemveliso | Ikhoyili yentsimbi yekhabhoni | |

| Umgangatho | I-ASTM, i-AISI, i-DIN, i-EN, i-BS, i-GB, i-JIS | |

| Ubukhulu | Iqengqeleke Ngobandayo: 0.2 ~ 6mm Ishushu Eqengqelekayo: 3 ~ 12mm | |

| Ububanzi | I-Cold Roled: 50~1500mm Ishushu Eqengqelekayo: 20 ~ 2000mm okanye isicelo somthengi | |

| Ubude | Ikhoyili okanye ngokwesicelo somthengi | |

| Ibanga | I-ASTM/ASME: A36, A283, A285, A514, A516, A572, A1011/A1011M | |

| GB: Q195, Q235/Q235B, Q255, Q275, Q345/Q345B, Q420, Q550, Q690 | ||

| I-JIS: SS400, G3131 SPHC, G3141 SPCC, G4051 S45C, G4051 S50C | ||

| AISI 1008, AISI 1015, AISI 1017, AISI 1021, AISI 1025, AISI 1026, AISI 1035, AISI 1045, AISI 1050, AISI 1055, AISI 4140, AISI 43410, AISI 43410, AISI 434101 8620, AISI 12L14 | ||

| I-SAE: 1010, i-SAE 1020, i-SAE 1045 | ||

| Ubuchule | Iqengqiwe ngobushushu / Iqengqiwe ngobushushu | |

| Uhlobo | Intsimbi ethambileyo / Intsimbi yekhabhoni ephakathi / Intsimbi yekhabhoni ephezulu | |

| Umphezulu | Ukwaleka, Ukuqhotsa, Ukuphosphating | |

| Ukucutshungulwa | Ukuwelda, Ukusika, Ukugoba, Ukuhombisa | |

Iimpawu zeekhemikhali ezisetyenziswa rhoqo

| Umgangatho | Ibanga | C% | Mn% | I-Si% | P% | S% | I-Cr% | I-Ni% | I-Cu% |

| I-JIS G3103 | I-SS330 | <0.050 | <0.050 | <0.20 | |||||

| SS400 | <0.050 | <0.050 | <0.20 | ||||||

| SS40 | <0.050 | <0.050 | <0.20 | ||||||

| I-JIS G4051-2005 | S15C | 0.13-0.18 | 0.30-0.60 | 0.15-0.35 | <0.030 | <0.035 | <0.20 | ||

| S20C | 0.18-0.23 | 0.30-0.60 | 0.15-0.35 | <0.030 | <0.035 | <0.20 | <0.20 | <0.20 | |

| I-ASTM A36 | I-ASTMA36 | <0.22 | 0.50-0.0 | <0.40 | <0.040 | <0.050 | <0.20 | <0.20 | <0.20 |

| I-ASTM A568 | SAE1015 | 0.13-0.18 | 0.30-0.60 | <0.040 | <0.050 | <0.20 | <0.20 | <0.30 | |

| SAE1017 | 0.15-0.20 | 0.30-0.60 | <0.040 | <0.050 | <0.20 | <0.20 | <0.30 | ||

| SAE1018 | 0.15-0.20 | 0.60-0.0 | <0.040 | <0.050 | <0.20 | <0.20 | <0.30 | ||

| SAE1020 | 0.15-0.20 | 0.30-0.60 | <0.040 | <0.050 | <0.20 | <0.20 | <0.30 | ||

| EN10025 | S235JR | 0.15-0.20 | <1.40 | <0.035 | <0.035 | <0.20 | |||

| S275JR | <0.22 | <1.40 | <0.035 | <0.035 | <0.20 |

Isicelo

Ipleyiti yentsimbi yekhabhoni ye-Q235 isetyenziswa kakhulu kumashishini ahlukeneyo, kubandakanya ulwakhiwo, ukwenziwa kwemveliso, iimoto, kunye nokuveliswa ngokubanzi, kwizinto zokwakha, iindawo zoomatshini, izikhongozeli, izixhobo zokwakha, nokunye.

Bhala umyalezo wakho apha uze uwuthumele kuthi