Ibha Engqukuva Yentsimbi Engagqwali Enomgangatho Olungileyo

Ulwakhiwo lwesakhiwo

Intsimbi (Fe): yinxalenye yesinyithi esisiseko yentsimbi engagqwaliyo;

I-Chromium (Cr): yeyona nto iphambili eyenza i-ferrite, i-chromium edityaniswe ne-oksijini inokuvelisa ifilimu yokudlulisa i-Cr2O3 engamelani nokugqwala, yenye yezona zinto zisisiseko zentsimbi engagqwaliyo ukugcina ukumelana nokugqwala, umxholo we-chromium unyusa amandla okulungisa ifilimu yokudlulisa i-passivation yentsimbi, umxholo we-chromium yentsimbi engagqwaliyo ngokubanzi kufuneka ube ngaphezulu kwe-12%;

I-Carbon (C): yinto enamandla yokwenza i-austenite, inokuphucula kakhulu amandla entsimbi, ukongeza kwi-carbon ekuchaseni ukugqwala nayo inempembelelo embi;

I-Nickel (Ni): yeyona nto iphambili eyenza i-austenite, inokucothisa ukugqwala kwentsimbi kunye nokukhula kweenkozo ngexesha lokufudumeza;

I-Molybdenum (Mo): yinto eyenza i-carbide, i-carbide eyenziweyo izinzile kakhulu, inokuthintela ukukhula kwengqolowa ye-austenite xa ishushu, inciphise uvakalelo lobushushu obukhulu bentsimbi, ukongeza, i-molybdenum inokwenza ifilimu yokuthambisa ibe nkulu kwaye iqine, ngaloo ndlela iphucula ngempumelelo ukumelana nokugqwala kwentsimbi engagqwaliyo;

I-Niobium, i-titanium (Nb, Ti): zizinto eziqinileyo ezenza i-carbide, zinokuphucula ukumelana kwentsimbi nokugqwala kwe-intergranular. Nangona kunjalo, i-titanium carbide inefuthe elibi kumgangatho womphezulu wentsimbi engagqwali, ngoko ke intsimbi engagqwali eneemfuno eziphezulu zomphezulu ngokubanzi iphuculwa ngokongeza i-niobium ukuphucula ukusebenza.

I-nitrogen (N): yinto enamandla yokwenza i-austenite, inokuphucula kakhulu amandla entsimbi. Kodwa ukuqhekeka okugugayo kwentsimbi engagqwali kunempembelelo enkulu, ngoko ke intsimbi engagqwali ekunyatheliseni ijolise ekulawuleni ngokungqongqo umxholo we-nitrogen.

I-Phosphorus, i-sulfur (P, S): yinto enobungozi kwintsimbi engagqwaliyo, ukumelana nokugqwala kunye nokunyatheliswa kwentsimbi engagqwaliyo kunokuba nefuthe elibi.

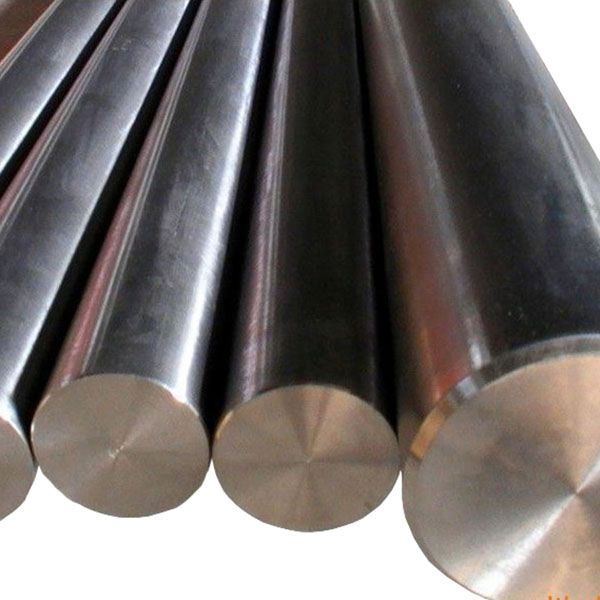

Umboniso weMveliso

Izinto kunye nokusebenza

| Izinto eziphathekayo | Iimpawu |

| Intsimbi engagqwaliyo ye-310S | Intsimbi engagqwaliyo ye-310S yintsimbi engagqwaliyo ye-chromium-nickel enokuxhathisa kakuhle i-oxidation, ukumelana nokugqwala, ngenxa yepesenti ephezulu ye-chromium kunye ne-nickel, i-310S inamandla angcono kakhulu okuhambahamba, ingaqhubeka nokusebenza kumaqondo obushushu aphezulu, kunye nokuxhathisa okuhle kumaqondo obushushu aphezulu. |

| Ibha engqukuva yentsimbi engagqwaliyo engama-316L | 1) Imbonakalo entle nekhazimlayo yeemveliso ezigoqiweyo ezibandayo. 2) ukumelana nokugqwala okugqwesileyo, ingakumbi ukumelana nokugqwala, ngenxa yokongezwa kweMo 3) amandla aphezulu obushushu; 4) ukuqina komsebenzi okugqwesileyo (iipropati ezibuthathaka zemagnethi emva kokucubungula) 5) i-non-magnetic ikwimeko yesisombululo esiqinileyo. |

| Intsimbi engagqwaliyo engama-316 intsimbi engqukuva | Iimpawu: I-316 stainless steel yintsimbi yesibini esetyenziswa kakhulu emva kwe-304, esetyenziswa kakhulu kwishishini lokutya nakwizixhobo zotyando, ngenxa yokongezwa kwe-Mo, ngoko ke ukumelana kwayo nokugqwala, ukumelana nokugqwala emoyeni kunye namandla obushushu aphezulu kulungile kakhulu, ingasetyenziswa kwiimeko ezinzima; ukuqina komsebenzi okugqwesileyo (okungengombane). |

| Intsimbi engagqwaliyo engama-321 yentsimbi engqukuva | Iimpawu: Ukongezwa kwezinto ze-Ti kwintsimbi ye-304 ukuthintela ukugqwala komda weenkozo, ezifanelekileyo ukusetyenziswa kumaqondo obushushu angama-430 ℃ - 900 ℃. Ngaphandle kokongezwa kwezinto ze-titanium ukunciphisa umngcipheko wokugqwala kwezinto, ezinye iimpawu ezifana ne-304 |

| Intsimbi engqukuva engatyiwayo engama-304L | Intsimbi engqukuva engagqwaliyo ye-304L luhlobo lwentsimbi engagqwaliyo ye-304 enomxholo ophantsi wekhabhoni kwaye isetyenziswa kwiindawo apho kufuneka i-welding. Umxholo ophantsi wekhabhoni unciphisa ukuna kwe-carbide kwindawo echaphazelekileyo bubushushu kufutshane ne-weld, nto leyo enokubangela ukugqwala kwe-intergranular (ukukhuhlana kwe-weld) kwentsimbi engagqwali kwiindawo ezithile. |

| Intsimbi engagqwaliyo engama-304 yentsimbi engqukuva | Iimpawu: I-304 stainless steel yenye yezona zisetyenziswa kakhulu kwi-chromium-nickel stainless steel, inokumelana nokugqwala okuhle, ukumelana nobushushu, amandla aphantsi obushushu kunye neempawu zoomatshini. Ukumelana nokugqwala emoyeni, ukuba umoya wezoshishino okanye iindawo zongcoliseko olunzima, kufuneka icocwe ngexesha ukuze kuthintelwe ukugqwala. |

Ukusetyenziswa Okuqhelekileyo

Intsimbi engqukuva yentsimbi engagqwaliyo inokusetyenziswa ngokubanzi kwaye isetyenziswa kakhulu kwizixhobo zekhompyutha nezekhitshi, ekwakheni iinqanawa, kwi-petrochemical, koomatshini, kumayeza, ekutyeni, kumbane, kumandla, kwi-aerospace, njl.njl., ekwakheni nasekuhombiseni. Izixhobo zokusetyenziswa emanzini olwandle, kwiikhemikhali, kwidayi, ephepheni, kwi-oxalic acid, kwizichumisi nakwezinye izixhobo zemveliso; ukufota, kushishino lokutya, kwiindawo zonxweme, kwiintambo, kwiintonga zeCD, kwiibholiti, kwiinuts.

Iimveliso eziphambili

Iibha ezingqukuva zentsimbi engagqwaliyo zingahlulwa zibe ziibha ezigoqiweyo ezishushu, ezenziwe ngobumba kunye nezitsalwa zibandayo ngokwenkqubo yemveliso. Iinkcazo zentsimbi engqukuva yentsimbi engagqwaliyo eshushu ye-5.5-250 mm. Phakathi kwazo: I-5.5-25 mm yentsimbi encinci engagqwaliyo ejikelezileyo enikezelwa kakhulu kwiibhanti zeebha ezithe tye, ezisetyenziswa rhoqo njengeebha zentsimbi, iibholiti kunye neendawo ezahlukeneyo zoomatshini; intsimbi engqukuva yentsimbi engagqwaliyo engaphezulu kwe-25 mm, esetyenziswa kakhulu ekwenziweni kweendawo zoomatshini okanye kwiibhilethi zentsimbi ezingenamthungo.