Ipleyiti yentsimbi engagqwaliyo

Ingcaciso yeMveliso

| Igama lemveliso | Ipleyiti/Iphepha leNtsimbi Engagqwaliyo |

| Umgangatho | I-ASTM, JIS, DIN, GB, AISI, DIN, EN |

| Izinto eziphathekayo | 201, 202, 301, 301L, 304, 304L, 316, 316L, 321, 310S, 904L, 410, 420J2, 430, 2205, 2507, 371, 4, 3, 4, 3, 4, 3, 4, 3, 4, 3 H 4, 4 409, 420, 430, 631, 904L, 305, 301L, 317, 317L, 309, 309S 310 |

| Ubuchule | Itsalwe ebandayo, Itshiswe eshushu, Itshiswe ebandayo nezinye. |

| Ububanzi | 6-12mm okanye ingenziwa ngokwezifiso |

| Ubukhulu | 1-120mm okanye ingenziwa ngokwezifiso |

| Ubude | 1000 - 6000mm okanye ingenziwa ngokwezifiso |

| Unyango Lomphezulu | BA/2B/NO.1/NO.3/NO.4/8K/HL/2D/1D |

| Imvelaphi | iTshayina |

| Ikhowudi ye-HS | 7211190000 |

| Ixesha lokuzisa | Iintsuku ezisi-7-15, kuxhomekeke kwimeko kunye nobungakanani |

| Inkonzo yasemva kokuthengisa | Iiyure ezingama-24 kwi-intanethi |

| Umthamo weMveliso | Iitoni ezili-100000/Ngonyaka |

| Imigaqo yeXabiso | EXW, FOB, CIF, CRF, CNF okanye ezinye |

| Izibuko Lokulayisha | Nasiphi na izibuko eTshayina |

| Ixesha lokuhlawula | TT, LC, Cash, Paypal, DP, DA, Western Union okanye ezinye. |

| Isicelo | 1. Ukuhombisa uyilo lwezakhiwo. Ezifana neendonga zangaphandle, iindonga zamakhethini, iisilingi, ii-handrails zezitebhisi, iingcango neefestile, njl.njl. |

| 2. Ifenitshala yasekhitshini. Ezifana nesitovu sasekhitshini, isinki, njl. | |

| 3. Izixhobo zekhemikhali. Ezifana nezikhongozeli, imibhobho, njl.njl. | |

| 4. Ukulungiswa kokutya. Ezifana nezikhongozeli zokutya, iitafile zokulungiswa, njl. | |

| 5. Ukwenziwa kweemoto. Ezifana nomzimba wemoto, umbhobho wokukhupha umoya, itanki yepetroli, njl.njl. | |

| 6. Izixhobo ze-elektroniki. Ezifana neekhabhathi zokwenza izinto, izinto zokwakha, njl.njl. zezixhobo ze-elektroniki. | |

| 7. Izixhobo zonyango. Ezifana nezixhobo zotyando, izixhobo zotyando, izixhobo zonyango, njl. | |

| 8. Ukwakhiwa kweenqanawa. Ezifana neenqanawa, imibhobho, izixhobo ezixhasayo, njl.njl. | |

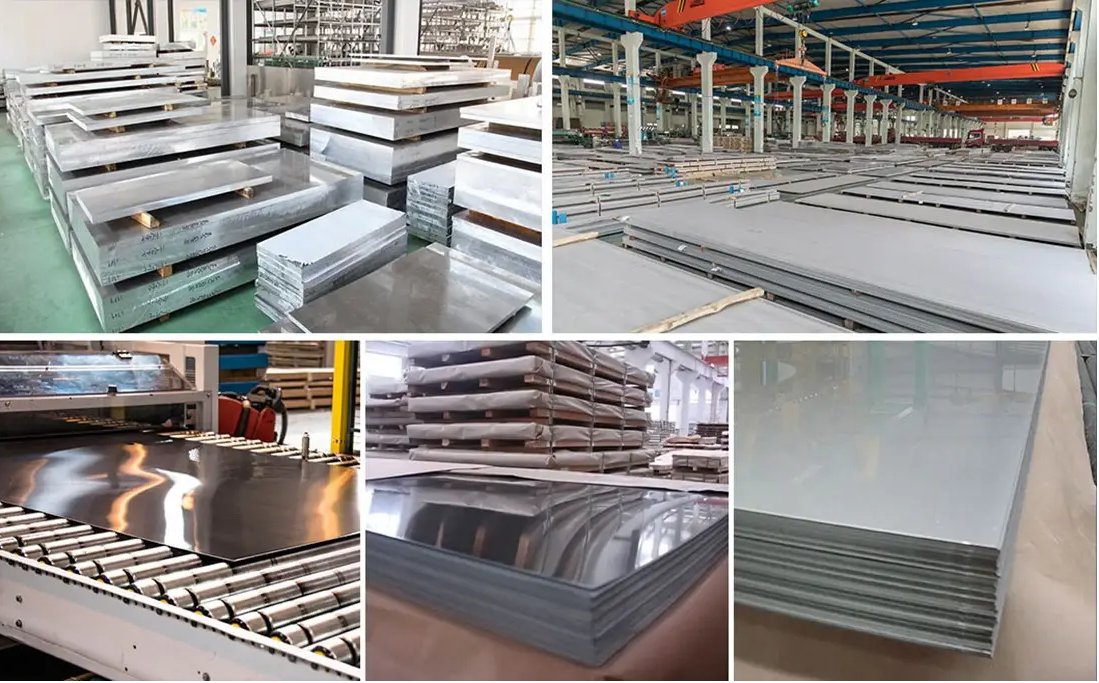

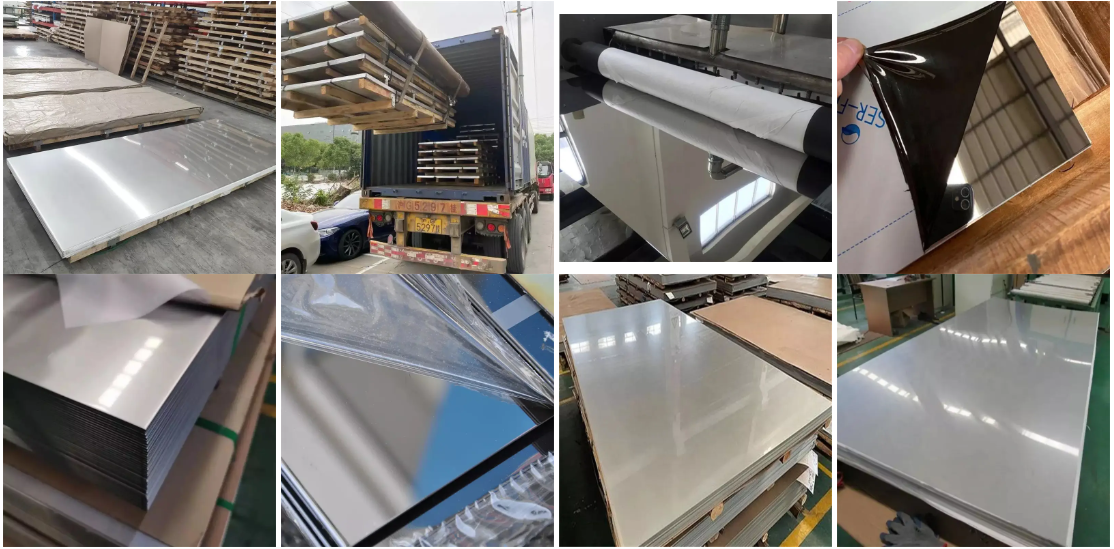

| Ukupakisha | Iphakheji, ibhegi yePVC, ibhande leNylon, intambo yokubopha, iphakheji eqhelekileyo yokuthumela ngaphandle elwandle okanye njengoko iceliwe. |

| Inkonzo Yokucubungula | Ukugoba, ukuWelda, ukuDecoiling, ukuBetha, ukuSika nezinye. |

| Ukunyamezelana | ±1% |

| I-MOQ | iitoni ezi-5 |

Ixesha lokukhokhela

| Ubungakanani (iitoni) | 1 - 50 | 51 - 100 | > 100 |

| Ixesha lokunikezelwa (iintsuku) | 7 | 15 | Kuza kuxoxiswana |

Inkcazo

| Imveliso | Iphepha leSinyithi esingenasici, iPlate yeSinyithi esingenasici |

| Uhlobo lwezinto | Intsimbi engagqwaliyo yeFerrite, enemagnethi; Intsimbi engagqwaliyo yaseAustenitic, engenamagnethi. |

|

Ibanga | Ngokuyintloko201, 202, 304, 304L, 304H, 316, 316L, 316Ti, 2205, 330, 630, 660, 409L, 321, 310S, 410, 416, 410S, 430, 347H, 2Cr13, 3Cr13 njl. |

| 300series: 301,302,303,304,304L,309,309s,310,310S,316,316L,316Ti,317L,321,347 | |

| Uthotho lwama-200:201,202,202cu,204 | |

| 400series: 409,409L,410,420,430,431,439,440,441,444 | |

| Ezinye: 2205,2507,2906,330,660,630,631,17-4ph,17-7ph, S318039 904L, njl. | |

| Intsimbi engagqwaliyo ephindwe kabini: S22053, S25073, S22253, S31803, S32205, S32304 | |

| Intsimbi Engagqwaliyo Ekhethekileyo: 904L, 347/347H, 317/317L, 316Ti, 254Mo | |

| Inzuzo | Sinesitokhwe, esimalunga neetoni ezingama-20000. Ukuhanjiswa kweentsuku ezisi-7-10, kungadluli kwiintsuku ezingama-20 zoku-odola ngobuninzi |

| Ubuchwepheshe | Iqengqiwe ebandayo/ Iqengqiwe eshushu |

| Ubude | 100~12000 mm/ njengoko kuceliwe |

| Ububanzi | 100~2000 mm/ njengoko kuceliwe |

| Ubukhulu | I-Cold Roll: 0.1 ~ 3 mm / njengoko kuceliwe |

|

| I-Hot Roll: 3 ~ 100 mm / njengoko kuceliwe |

|

Umphezulu | BA, 2B, 2D, 4K, 6K, 8K, NO.4, HL, SB, Embossed |

| Ukulinganisa: phucula ukuthamba, ingakumbi izinto ezicelwe ukuthamba okuphezulu. | |

| I-Skin-Pass: iphucula ukuthamba, ukukhanya okuphezulu | |

| Ezinye iindlela zokukhetha | Ukusika: Ukusika nge-laser, nceda umthengi ukuba asike ubungakanani obufunekayo |

| Ukhuseleko | 1. Iphepha eliphakathi liyafumaneka |

| 2. Ifilimu yokukhusela iPVC iyafumaneka | |

| Ngokwesicelo sakho, ubungakanani ngabunye bunokukhethwa ngokwesicelo esahlukileyo. Nceda unxibelelane nathi! | |

Unyango Lomphezulu

| Umphezulu | Inkcazo | Isicelo |

| INOMBOLO 1 | Umphezulu ugqitywe ngonyango lobushushu kunye nokucola okanye iinkqubo ihambelana naleyo emva kokuqengqeleka okushushu. | Itanki yeekhemikhali, umbhobho |

| 2B | Ezo zigqityiweyo, emva kokuqengqeleka ngokubandayo, ngokunyangwa ngobushushu, ngokugalelwa okanye ngolunye unyango olulinganayo kwaye ekugqibeleni ngokuqengqeleka ngokubandayo ukuya kwinani elinikiweyo. ukukhazimla okufanelekileyo. | Izixhobo zonyango, Ishishini lokutya, Izinto zokwakha, Izixhobo zasekhitshini. |

| Inombolo 3 | Ezo zigqityiwe ngokupolisha ngee-abrasives zeNombolo 100 ukuya kwiNombolo 120 ezichazwe kwi-JIS R6001. | Izixhobo zasekhitshini, Ulwakhiwo lwesakhiwo |

| Inombolo 4 | Ezo zigqityiwe ngokupolisha ngee-abrasives zeNombolo 150 ukuya kwiNombolo 180 ezichazwe kwi-JIS R6001. | Izixhobo zasekhitshini, Ulwakhiwo lwezakhiwo, Izixhobo zonyango. |

| HL | Ezo zigqityiweyo zokupolisha ukuze zinike imicu yokupolisha eqhubekayo ngokusebenzisa i-abrasive enobukhulu obufanelekileyo bengqolowa | Ukwakhiwa kweZakhiwo. |

| BA (Inombolo 6) | Ezo zicutshungulwa ngonyango olushushu olukhanyayo emva kokuqengqeleka okubandayo. | Izixhobo zasekhitshini, Izixhobo zombane, Ukwakhiwa kwezakhiwo. |

| Isibuko (Inombolo yesi-8) | Ukukhanya njengesipili | Ukwakhiwa kwezakhiwo |

Ukupakisha kunye nokuHanjiswa

FAQ

Q1: Ixesha lakho lokuhambisa lithatha ixesha elingakanani?

A: Ngokubanzi, ixesha lethu lokuhambisa lingaphakathi kweentsuku eziyi-7-45, ukuba kukho imfuneko enkulu okanye iimeko ezikhethekileyo, linokulibaziseka.

Q2: Zeziphi iziqinisekiso ezinazo iimveliso zakho?

A: Sine-ISO 9001, SGS, EWC kunye nezinye iziqinisekiso.

Q3: Zithini iindawo zokuthumela impahla?

A: Ungakhetha ezinye iiports ngokweemfuno zakho.

Q4: Ngaba ungathumela iisampulu?

A: Ewe kona, singathumela iisampulu kwihlabathi liphela, iisampulu zethu zisimahla, kodwa abathengi kufuneka bathwale iindleko zekorivariya.

Umbuzo 5: Loluphi ulwazi lwemveliso ekufuneka ndilunike?

A: Kufuneka unikezele ngenqanaba, ububanzi, ubukhulu kunye netoni ekufuneka uyithenge.

Umbuzo 6: Yintoni inzuzo yakho?

A: Ishishini elithembekileyo elinexabiso elikhuphisanayo kunye nenkonzo yobungcali kwinkqubo yokuthumela ngaphandle.