Ikhoyili yentsimbi engenasiciUmenzi, ipleyiti/iphepha lesinyithi esingenasici, i-SS coil/strip Umthumeli ngaphandle eTSHAYINA.

Yenziwe ngentsimbi eshayinayoEkuqaleni iveliswa kwiislabs, ezithi emva koko zifakwe kwinkqubo yokuguqula kusetyenziswa i-Z mill, eguqula i-slab ibe yi-coil ngaphambi kokuba iqengqeleke ngakumbi. Ezi coil zibanzi zihlala zenziwa malunga ne-1250mm (ngamanye amaxesha zibanzi kancinci) kwaye zaziwa ngokuba 'zii-mill edge coils'.

Ezi coils zibanzi zicutshungulwa ngakumbi kusetyenziswa iindlela ezahlukeneyo zokwenza ezinje ngokusika, apho coil ebanzi ikrazulwa ibe yimicu emininzi; kulapho uninzi lwe

kungena ukudideka malunga nesigama. Emva kokunqunyulwa,

Intsimbi engatyiwayo yenza iqela leekhoyili ezithathwe kwikhoyili kamama kwaye ezi zibizwa ngamagama amaninzi ahlukeneyo, kuquka iikhoyili zestrip, iikhoyili zeslit, iibanding okanye ii-simply strips.

Indlela iikhoyili ezijijekileyo ngayo inokubangela ukuba kusetyenziswe amagama ahlukeneyo kuzo. Uhlobo oluqhelekileyo lwaziwa ngokuba yi-'pancake coil', ebizwa ngegama lendlela ejongeka ngayo i-coil xa ibekwe ngokuthe tyaba; 'ribbon wound' lelinye igama lale ndlela yokujijela.

Olunye uhlobo lokujikajika yi-'traverse' okanye 'Oscillated', ekwaziwa ngokuba yi-'bobbin wound' okanye 'spool' ngenxa yokuba ijongeka njenge-bobbin yomqhaphu ngamanye amaxesha ezi zinokugotywa ngokwasemzimbeni kwi-spool yeplastiki. Ukuvelisa i-coil ngale ndlela kuvumela ukuba kuveliswe ii-coil ezinkulu kakhulu, nto leyo ekhokelela ekuzinzeni okuphuculweyo kunye nemveliso engcono.

Ikhoyili yentsimbi engenasici eqengqelekayo ebandayo

Ikhoyili yentsimbi engagqwaliyo ijikeleziswa yi-cold rolling mill kubushushu begumbi. Ubukhulu obuqhelekileyo buqala kwi-0.1 mm ukuya kwi-3 mm kwaye ububanzi buqala kwi-100 mm ukuya kwi-2000 mm.

Ikhoyili yentsimbi engenasici eqengqelekayo ebandayo

Inezibonelelo zomphezulu ogudileyo, umphezulu othe tyaba, ukuchaneka okuphezulu kunye nokulunga

iipropati zoomatshini. Uninzi lweemveliso ziqengqeleka kwaye zinokucutshungulwa zibe ziishiti zentsimbi ezigqunyiweyo.

Inkqubo yokuvelisa i-coil yentsimbi engagqwali eqengqekileyo ebandayo yi-pickling, i-rolling yobushushu obuqhelekileyo, i-lubrication, i-annealing,

ukulinganisa, ukusika kakuhle kunye nokupakishwa.

Ikhoyili yentsimbi engagqwaliyo eshushu eqengqelekayo

Yenziwe nge-hot coil mill enobukhulu obuyi-1.80mm-6.00mm kunye nobubanzi obuyi-50mm-1200mm. Intsimbi engagqwaliyo eshushu ineengenelo zobunzima obuphantsi, ukucutshungulwa okulula kunye nokuguquguquka okuhle. Iinkqubo zayo zemveliso kukukha, ukuqengqeleka ngobushushu obuphezulu, ukuthambisa ngenkqubo, ukuqhoboshela, ukulinganisa, ukugqiba kunye nokupakishwa.

Kukho umahluko omkhulu phakathi kwekhoyili yentsimbi engagqwaliyo ebandayo kunye nekhoyili yentsimbi engagqwaliyo eshushu.

Okokuqala, amandla kunye nokuqina kwekhoyili yentsimbi engagqwaliyo ebandayo kubhetele, kwaye ukuguquguquka kunye nokuqina kwekhoyili yentsimbi engagqwaliyo eshushu kubhetele. Okwesibini, ubukhulu bekhoyili yentsimbi engagqwaliyo ebandayo buncinci kakhulu, ngelixa obo bekhoyili yentsimbi engagqwaliyo eshushu bukhulu. Ukongeza, umgangatho womphezulu, inkangeleko kunye nokuchaneka kobukhulu bekhoyili yentsimbi engagqwaliyo ebandayo kubhetele kunezo zekhoyili yentsimbi engagqwaliyo eshushu.

UNYANGO OLUNGEZELELWEYO

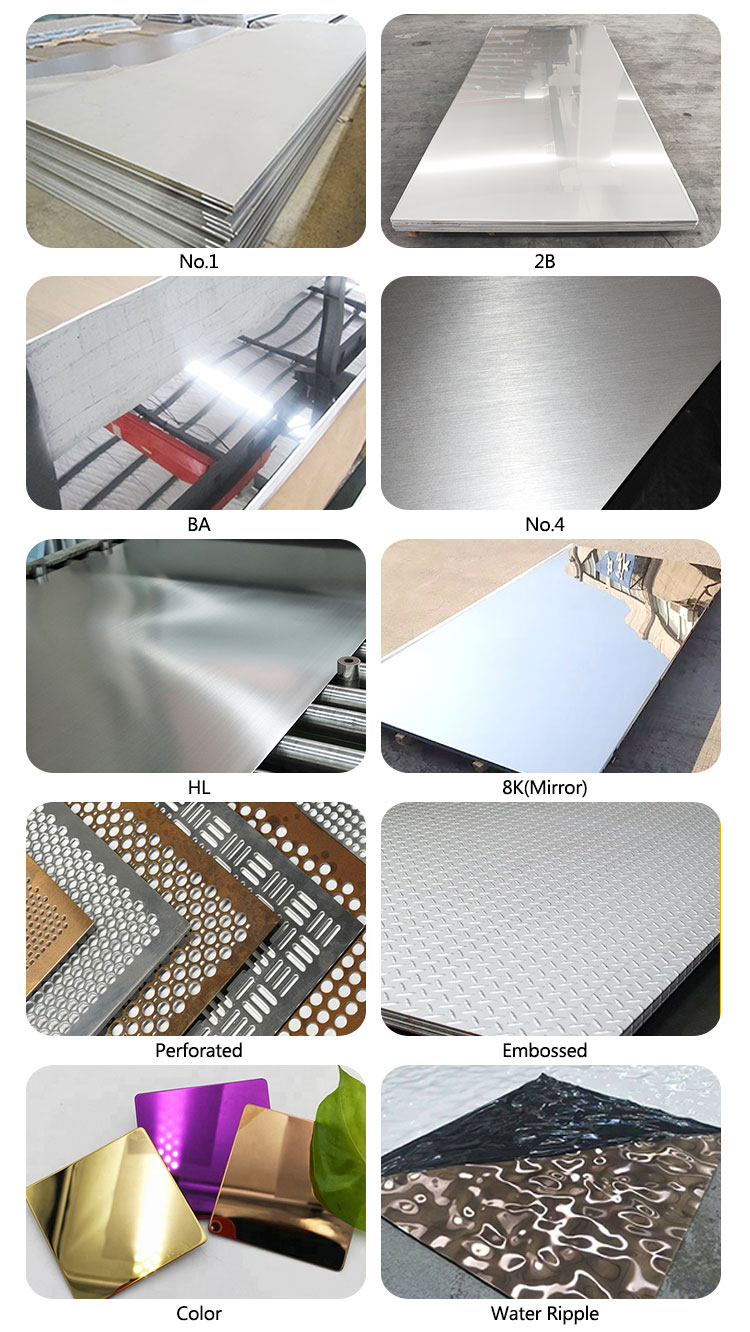

Sinezixhobo ezivela kwamanye amazwe kunye neenjineli ezingoochwephesha, ngoko ke umphezulu wepleyiti yethu yentsimbi engagqwaliyo uphezulu kakhulu kunokuba abathengi bebekulindele.

| Umphezulu | Uphawu | Itekhnoloji yokucubungula |

| N0.1 | Yoqobo | Ifakwe i-pickle emva kokuqengqeleka okushushu |

| 2D | I-Blunt | Ukuqengqeleka okushushu + ukuxutywa kwe-annealing shot peening pickling + ukuqengqeleka okubandayo + ukugquma i-annealing pickling |

| 2B | Ifiphalisiwe | Ukuqengqeleka okushushu + ukuxutywa kwe-annealing shot peening pickling + ukuqengqeleka okubandayo + ukugquma kwe-annealing + ukuqengqeleka kwe-tempering |

| N0.3 | Matte | Ukupolisha kunye nokujika okuthambileyo ngezinto ezirhabaxa ze-100-120 mesh |

| N0.4 | Matte | Ukupolisha kunye nokujika okuthambileyo ngezinto ezirhabaxa ze-150-180 mesh |

| NO.240 | Matte | Ukupolisha kunye nokujika okuthambileyo ngezinto ezingama-240 ze-mesh abrasive |

| NO.320 | Matte | Ukupolisha kunye nokujika okuthambileyo ngezinto ezirhabaxa ezingama-320 |

| NO.400 | Matte | Ukupolisha kunye nokujika okuthambileyo ngezinto ezirhabaxa ezingama-400 |

| HL | Ibhrashiwe | Gaya umphezulu webhanti yentsimbi ngobukhulu obufanelekileyo bengqolowa yokugaya ukuze ubonise ubume obude obuthile |

| BA | Qazileyo | Umphezulu uvaliwe kwaye ubonisa ukukhanya okuphezulu |

| 6K | Isibuko | Ukugaywa nokupholishwa okurhabaxa |

| 8K | Isibuko | Ukugaya nokupolisha kakuhle |

Ixesha lokuthumela: Epreli-07-2023