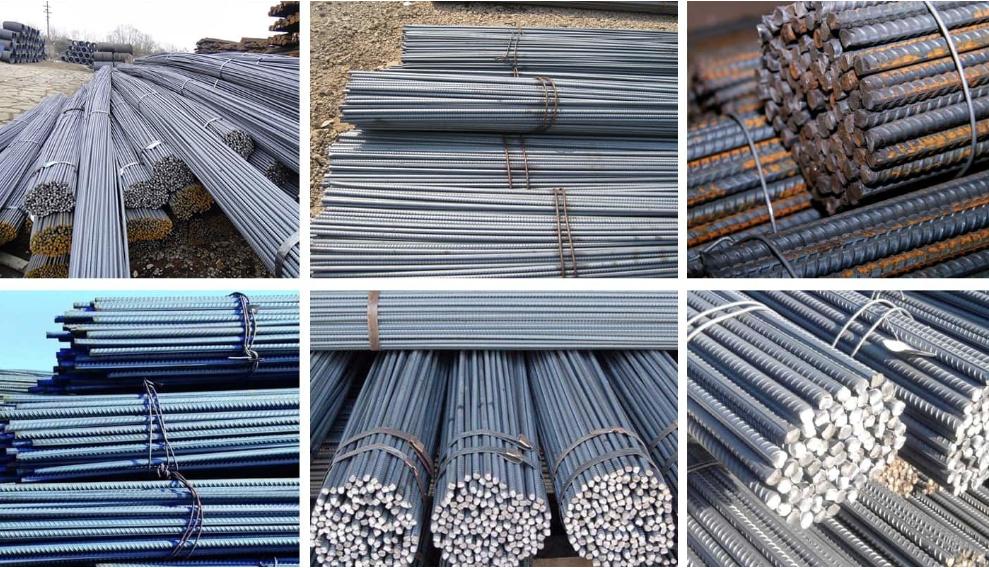

Ibha Yokuqinisa Intsimbi Yekhabhoni (I-Rebar)

Ingcaciso yeMveliso

| Ibanga | I-HPB300, i-HRB335, i-HRB400, i-HRBF400, i-HRB400E, i-HRBF400E, i-HRB500, i-HRBF500, i-HRB500E, i-HRBF500E, i-HRB600, njl. |

| Umgangatho | GB 1499.2-2018 |

| Isicelo | I-rebar yentsimbi isetyenziswa kakhulu kwizakhiwo zekhonkrithi. Ezi ziquka umgangatho, iindonga, iintsika, kunye neminye imisebenzi ebandakanya ukuthwala imithwalo enzima okanye engaxhaswanga ngokwaneleyo ukuba ibambe ikhonkrithi kuphela. Ngaphandle kwezi zixhobo, i-rebar ikwaphuhlise ukuthandwa kwizicelo zokuhombisa ezifana namasango, ifenitshala, kunye nobugcisa. |

| *Nazi ubungakanani obuqhelekileyo kunye neemfuno ezisemgangathweni, ezikhethekileyo nceda unxibelelane nathi | |

| Ubungakanani obuqhelekileyo | Ububanzi (ngaphakathi) | Ububanzi(mm) | Ubungakanani obuqhelekileyo | Ububanzi (ngaphakathi) | Ububanzi(mm) |

| #3 | 0.375 | 10 | #8 | 1.000 | 25 |

| #4 | 0.500 | 12 | #9 | 1.128 | 28 |

| #5 | 0.625 | 16 | #10 | 1.270 | 32 |

| #6 | 0.750 | 20 | #11 | 1.140 | 36 |

| #7 | 0.875 | 22 | #14 | 1.693 | 40 |

| Ikhowudi yeRebar yaseTshayina | Amandla Okuvelisa (i-Mpa) | Amandla okuThamba (i-Mpa) | Umxholo weCarbon |

| HRB400, HRBF400, HRB400E, HRBF400E | 400 | 540 | ≤0.25 |

| HRB500, HRBF500, HRB500E, HRBF500E | 500 | 630 | ≤0.25 |

| I-HRB600 | 600 | 730 | ≤ 0.28 |

Iinkcukacha zeMveliso

Inkcazo ye-ASTM A615 Reinforceing Bar Grade 60

I-ASTM A615 Steel Rebar yonyusa amandla okutsalwa kwekhonkrithi kwaye ingasetyenziselwa zombini ukuqinisa okuphambili nokwesibini. Inceda ukufunxa uxinzelelo kunye nobunzima kwaye yenza kube lula ukusasazwa ngokulinganayo koxinzelelo olubangelwa kukwanda kunye nokuncitshiswa kwekhonkrithi xa ivezwa kubushushu nokubanda, ngokulandelelana.

I-ASTM A615 Steel Rebar inomphetho orhabaxa, oluhlaza okwesibhakabhaka-ngwevu kunye neembambo eziphakanyisiweyo kuyo yonke ibha. I-ASTM A615 Grade 60 Steel Rebar inika amandla okuvelisa aphuculweyo ubuncinane iipawundi ezingama-60 amawaka ngesikwere intshi, okanye ii-megapascal ezingama-420 kwisikali sokulinganisa i-metric. Ikwanomgca oqhubekayo, kunye nomgca omnye ohamba kubude bebha ohambelana nezithuba ezintlanu ukusuka embindini. Ezi mpawu zenza i-Grade 60 Steel Rebar ifaneleke kakhulu kwizicelo zokuqinisa ikhonkrithi eziphakathi ukuya kwezinzima.

| Iinkcukacha ze-ASTM A615 American Rebar | ||||

| UMGANGATHO (mm.) | UBUDE (m.) | INANI LEZINTO EZINGAKUMBI (UBUNINZI) | I-ASTM A 615 / M Ibanga lama-60 | |

| kg/m. | UBUNZIMA BETHIYORI YEBHUNDLE (Kg.) | |||

| 8 | 12 | 420 | 0.395 | 1990.800 |

| 10 | 12 | 270 | 0.617 | 1999.080 |

| 12 | 12 | 184 | 0.888 | 1960.704 |

| 14 | 12 | 136 | 1.208 | 1971.456 |

| 16 | 12 | 104 | 1.578 | 1969.344 |

| 18 | 12 | 82 | 2.000 | 1968.000 |

| 20 | 12 | 66 | 2.466 | 1953.072 |

| 22 | 12 | 54 | 2.984 | 1933.632 |

| 4 | 12 | 47 | 3.550 | 2002.200 |

| 25 | 12 | 42 | 3.853 | 1941.912 |

| 26 | 12 | 40 | 4.168 | 2000.640 |

| 28 | 12 | 33 | 4.834 | 1914.264 |

| 30 | 12 | 30 | 5.550 | 1998.000 |

| 32 | 12 | 26 | 6.313 | 1969.656 |

| 36 | 12 | 21 | 7.990 | 2013.480 |

| 40 | 12 | 17 | 9.865 | 2012.460 |

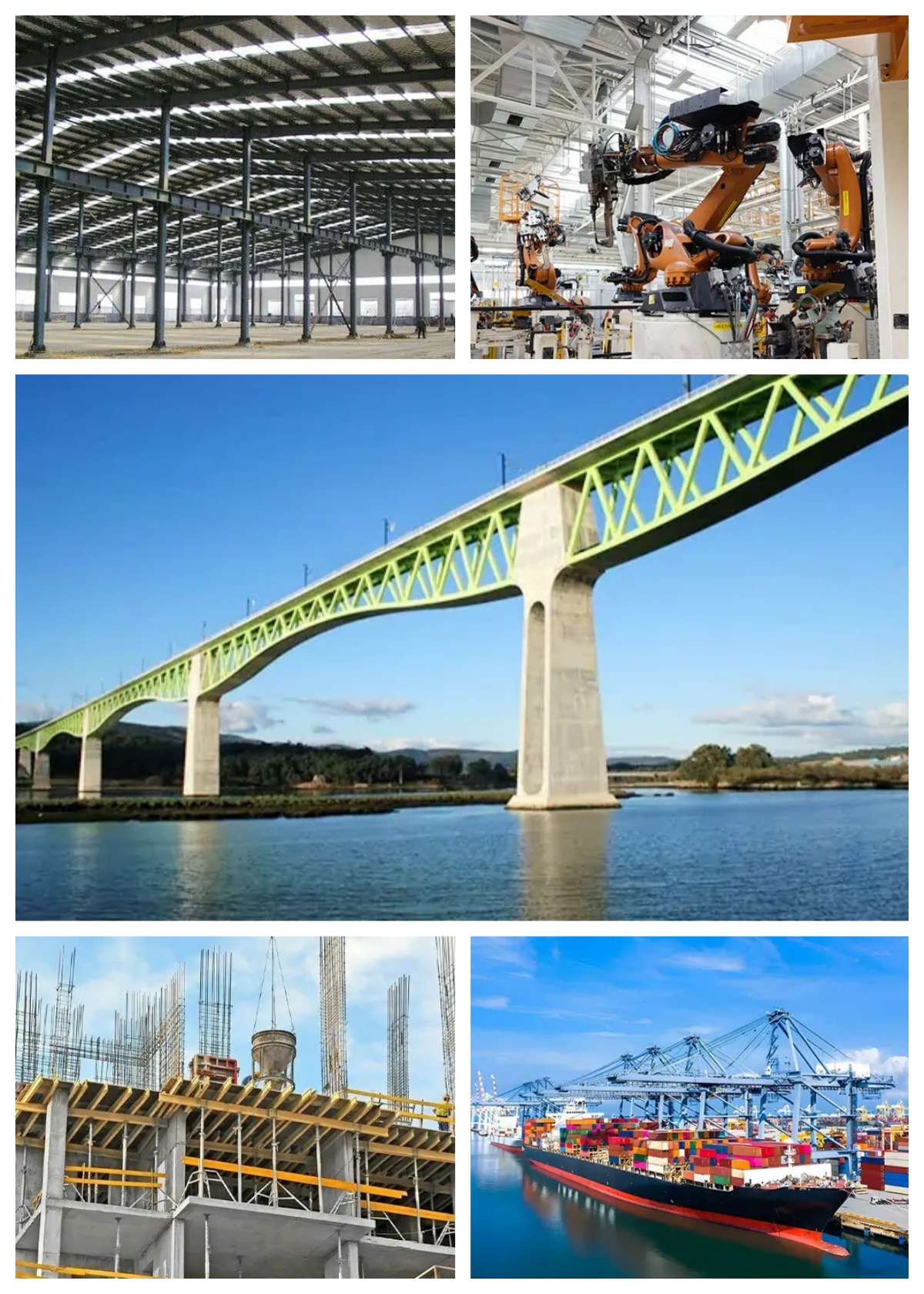

Ububanzi besicelo

Isetyenziswa kakhulu ezindlwini, kwiibhulorho, ezindleleni, ingakumbi koololiwe nakwezinye iindlela zobunjineli bokwakha.

Amandla okubonelela

| Amandla okubonelela | Iitoni ezingama-2000 ngenyanga |

Ixesha lokukhokhela

| Ubungakanani (iitoni) | 1-50 | 51-500 | 501-1000 | > 1000 |

| Ixesha lokunikezelwa (iintsuku) | 7 | 10 | 15 | Kuza kuxoxiswana |

UKUPAKISHA NOKUHANJISWA

Singabonelela,

ukupakishwa kwepallet yomthi,

Ukupakisha ngomthi,

Ukupakishwa kwentambo yentsimbi,

Ukupakisha ngeplastiki kunye nezinye iindlela zokupakisha.

Sizimisele ukupakisha nokuthumela iimveliso ngokwesisindo, iinkcukacha, izixhobo, iindleko zoqoqosho kunye neemfuno zabathengi.

Singabonelela ngezothutho lweekhonteyina okanye ezinkulu, iindlela zokuthutha amanzi, oololiwe okanye angaphakathi kunye nezinye iindlela zokuthutha emhlabeni ukuze zithunyelwe kwamanye amazwe. Kakade ke, ukuba kukho iimfuno ezikhethekileyo, singasebenzisa nezothutho zomoya.