Ikhoyili yentsimbi yekhabhoni ye-ST37

Ingcaciso yeMveliso

Intsimbi ye-ST37 (izinto eziyi-1.0330) yipleyiti yentsimbi yesinyithi ekumgangatho ophezulu egqunywe ngekhabhoni ephantsi eyenziwe ngendlela ebandayo yaseYurophu. Kwimigangatho ye-BS kunye ne-DIN EN 10130, ibandakanya ezinye iintlobo ezintlanu zentsimbi: DC03 (1.0347), DC04 (1.0338), DC05 (1.0312), DC06 (1.0873) kunye ne-DC07 (1.0898). Umgangatho womphezulu wahlulwe waba ziintlobo ezimbini: DC01-A kunye ne-DC01-B.

DC01-A: Iziphene ezingachaphazeli ukwakheka okanye ukugqunywa komphezulu ziyavunyelwa, njengemingxunya yomoya, ukuqhekeka okuncinci, amabala amancinci, imikrwelo emincinci kunye nombala omncinci.

DC01-B: Umphezulu ongcono kufuneka ungabi naziphene ezinokuchaphazela inkangeleko efanayo yepeyinti yomgangatho ophezulu okanye i-electrolytic coating. Omnye umphezulu kufuneka uhlangabezane ubuncinane nomgangatho womphezulu u-A.

Iindawo eziphambili zokusetyenziswa kwezixhobo ze-DC01 ziquka: ishishini leemoto, ishishini lokwakha, ishishini lezixhobo ze-elektroniki kunye nezixhobo zasekhaya, iinjongo zokuhombisa, ukutya okusemathinini, njl.

Iinkcukacha zeMveliso

| Igama lemveliso | Ikhoyili yentsimbi yekhabhoni |

| Ubukhulu | 0.1mm - 16mm |

| Ububanzi | 12.7mm - 1500mm |

| Ikhoyili Yangaphakathi | 508mm / 610mm |

| Umphezulu | Ulusu olumnyama, ukuqhola, ukuoyila, njl.njl. |

| Izinto eziphathekayo | S235JR, S275JR, S355JR, A36, SS400, Q235, Q355, ST37, ST52, SPCC, SPHC, SPHT, DC01, DC03, njl. |

| Umgangatho | GB, GOST, ASTM, AISI, JIS, BS, DIN, EN |

| Ubuchwepheshe | Ukuqengqeleka okushushu, Ukuqengqeleka okubandayo, Ukuqhola |

| Isicelo | Isetyenziswa kakhulu kwimveliso yoomatshini, ulwakhiwo, imveliso yeemoto nakwezinye iindawo |

| Ixesha lokuthunyelwa | Kwiintsuku ezili-15 ukuya kwezingama-20 zokusebenza emva kokufumana idiphozithi |

| Ukupakisha ngaphandle | Iphepha elingangeni manzi, kunye nomcu wentsimbi opakishwe. Iphakheji eqhelekileyo yokuthumela ngaphandle elwandle. Ifanelekile kuzo zonke iintlobo zothutho, okanye njengoko kufuneka |

| Ubungakanani obuncinci be-oda | Iitoni ezingama-25 |

Inzuzo ephambili

Ipleyiti yokuqhobosha yenziwe ngephepha elinomgangatho ophezulu eligoqwe ngobushushu njengezinto eziluhlaza. Emva kokuba iyunithi yokuqhobosha isuse umaleko we-oxide, inqumle kwaye igqibezele, umgangatho womphezulu kunye neemfuno zokusetyenziswa (ngokuyintloko ukusebenza okwenziwe ngokubandayo okanye ukuqiniswa) ziphakathi kokuqhobosha okushushu kunye nokugoqwe okubandayo. Imveliso ephakathi phakathi kweepleyiti yindawo efanelekileyo yokuthatha indawo yeepleyiti ezigoqwe ngobushushu kunye neepleyiti ezigoqwe ngobushushu. Xa kuthelekiswa neepleyiti ezigoqwe ngobushushu, iingenelo eziphambili zeepleyiti ezigoqwe ngobushushu zezi: 1. Umgangatho olungileyo womphezulu. Ngenxa yokuba iipleyiti ezigoqwe ngobushushu zisusa isikali se-oxide yomphezulu, umgangatho womphezulu wentsimbi uyaphucuka, kwaye kulula ukuwelda, ukutshiza ioyile kunye nokupeyinta. 2. Ukuchaneka kobukhulu kuphezulu. Emva kokulinganisa, imo yepleyiti ingatshintshwa ukuya kwinqanaba elithile, ngaloo ndlela kuncitshiswe ukuphambuka kokungalingani. 3. Ukuphucula ukugqitywa komphezulu kunye nokuphucula isiphumo sokubonakala. 4. Inokunciphisa ungcoliseko lokusingqongileyo olubangelwa kukuqhobosha okusasazekayo kwabasebenzisi. Xa kuthelekiswa neepleyiti ezigoqwe ngobushushu, inzuzo yeepleyiti ezigoqwe ngobushushu kukuba zinokunciphisa ngempumelelo iindleko zokuthenga ngelixa ziqinisekisa iimfuno zomgangatho womphezulu. Iinkampani ezininzi ziye zabeka phambili iimfuno eziphezulu neziphezulu zokusebenza okuphezulu kunye neendleko eziphantsi zentsimbi. Ngokuqhubeka nokuqhubela phambili kwetekhnoloji yokuqengqeleka kwentsimbi, ukusebenza kweshiti eqengqelekayo eshushu kusondela kweshiti eqengqelekayo ebandayo, ukuze "ukutshintshwa kokubanda ngobushushu" kufezekiswe ngobuchwephesha. Kunokuthiwa ipleyiti eqhotsiweyo yimveliso enomlinganiselo ophezulu wokusebenza-nexabiso phakathi kwepleyiti eqhotsiweyo ebandayo kunye nepleyiti eqhotsiweyo eshushu, kwaye inethuba elihle lokuphuhliswa kwemarike. Nangona kunjalo, ukusetyenziswa kweepleyiti eziqhotsiweyo kumashishini ahlukeneyo kwilizwe lam kusandula ukuqala. Ukuveliswa kweepleyiti zobungcali eziqhotsiweyo kwaqala ngoSeptemba 2001 xa umgca wemveliso ye-pickling kaBaosteel waqala ukusebenza.

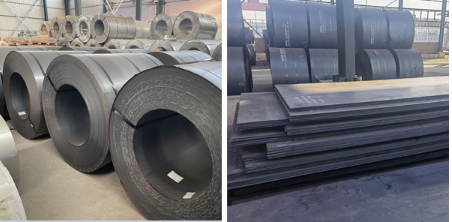

Umboniso wemveliso

Ukupakisha kunye nokuthumela

Sigxile kubathengi kwaye sizama ukubonelela abathengi ngeemveliso ezisemgangathweni ophezulu kunye namaxabiso angcono ngokweemfuno zabo zokusika nokuqengqa. Sibonelela abathengi ngeenkonzo ezilungileyo kwimveliso, ukupakisha, ukuhambisa kunye nokuqinisekisa umgangatho, kwaye sibonelela abathengi ngokuthenga kube kanye. Ke ngoko, ungathembela kumgangatho wethu kunye nenkonzo yethu.